Wisedo Implant

A thinking brain | Bright eyes |

Flexible fingers entering the machine

Intelligence and automation are the core development direction of the fluid controlling jewelry industry and press on nail industry . Dispensing and stone setting equipment based on artificial intelligence, machine visual, laser point cloud and video & image DL technology can achieve highly automatic production management and quality control, greatly improving production efficiency and products consistency .

All software of Wisedo equipment is independently developed, and the R&D team is constantly upgrading and iterating. The latest version of software products will be shared with Wisedo customers free of charge, so that customers can purchase once and iterate for life.

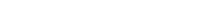

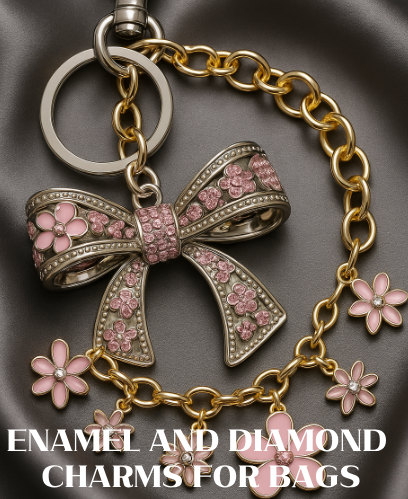

Our Jewelry Diamond Setting Robot and Jewelry Enamel Coloring Machine adopted visible technology deeply loved by customers because of easy operation, high precision and efficiency and good after service.

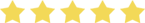

High Precision Jewelry Wax Stone Setting Machine

With 3D Laser Camera Image Fusion Technolgy

to Automatic Set Gemtone in Jewelry Wax Mold

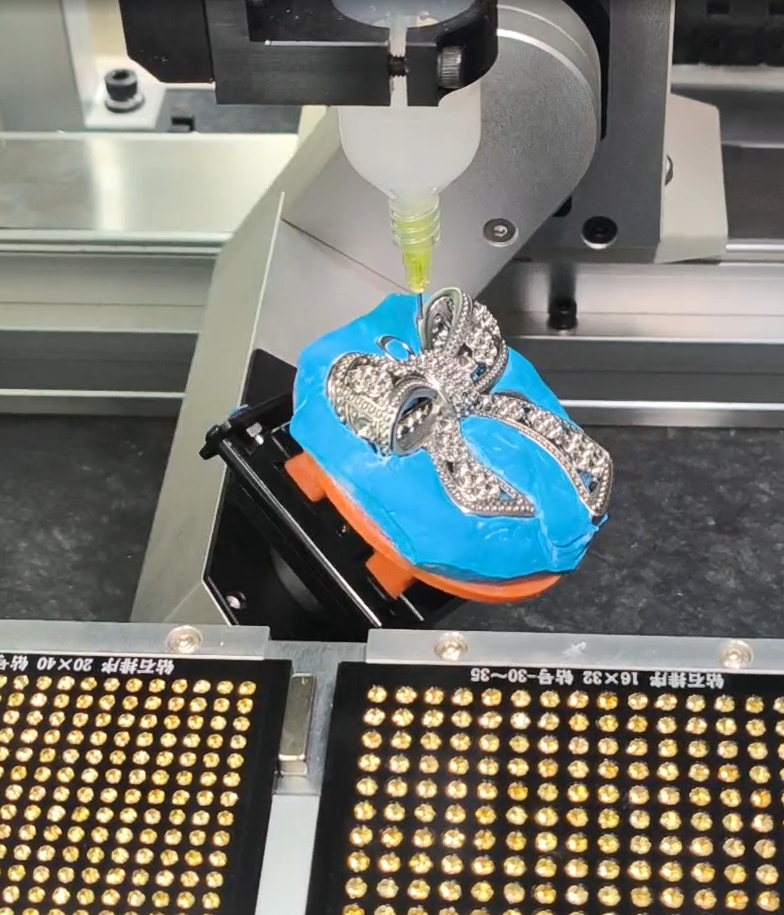

Intelligent Visual Jewelry Enamel Coloring

Machine Installed High Resolution

CCD Camera

Wisedo intelligent equipment (Guangdong) Co., Ltd. is a national high-tech enterprise integrating R&D, manufacturing, marketing, and technical service. Located in Dongguan, Guangdong Province — a globally recognized industrial hub — Wisedo has over 18 years of experience in automation technology.

We have built strong capabilities in IoT integration, machine vision systems, motion control, and precision liquid dispensing, 3D space image technology . With complete in-house software and hardware development teams, Wisedo holds multiple utility model patents and software copyrights. Several of our products have been certified as National High-Tech Products by the Software Industry Association.

Wisedo – High-Precision Jewelry Equipment Manufacturer

Wisedo specializes in designing, developing, and producing high-precision, high-efficiency machinery for the jewelry industry. Our solutions are widely applied in imitation jewelry production and high-end metal tag manufacturing.

We offer two core automation jewelry equipment series :

Intelligent Jewelry Diamond Stone Setting Machines

Intelligent Jewelry Enamel Coloring Machines

Driven by continuous innovation and customer-focused customization, our advanced equipment helps jewelry manufacturers improve quality, consistency, and productivity. From stone setting to enamel coloring, Wisedo delivers complete automated solutions for producing elegant, high-quality fashion and imitation jewelry.

Find quick answers about Wisedo’s jewelry equipment, including automatic diamond stone setting machines and enamel coloring robots. Learn how our machines improve accuracy, automate production, and support customized solutions for diverse jewelry manufacturing needs.

(1).jpg)

.jpg)